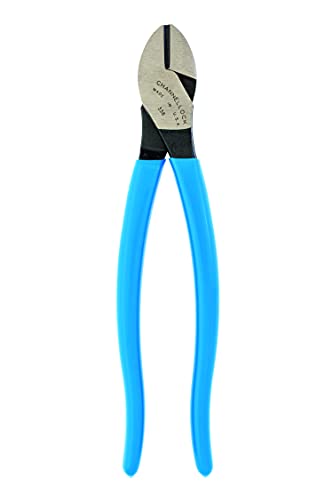

Channellock 338 High Leverage High Leverage Diagonal Cutters, 8-Inch

Last updated: June 9, 2020

We looked at the top Diagonal Cutters and dug through the reviews from some of the most popular review sites. Through this analysis, we've determined the best Diagonal Cutter you should buy.

Product Details

In our analysis, the Channellock Channellock 338 High Leverage High Leverage Diagonal Cutters, 8-Inch placed 7th when we looked at the top 11 products in the category. For the full ranking, see below.

From The Manufacturer

Not all cutting edges are the same. The 8-inch Channellock 338 Diagonal Cutting Plier uses precision machined knife and anvil style cutting edges to ensure perfect mating and superior cutting edge life. Channellock uses high carbon C1080 steel for superior performance on the job, and an electronic coating for ultimate rust prevention. It’s completed by Channellock’s iconic blue handle, which is both comfortable in your hand and easy to spot in your tool bag.