The Best Serpentine Belt Tool

We looked at the top 11 Serpentine Belt Tools and dug through the reviews from 2 of the most popular review sites including and more. The result is a ranking of the best Serpentine Belt Tools.

Our Review Process

Don't Waste Your Money is focused on helping you make the best purchasing decision. Our team of experts spends hundreds of hours analyzing, testing, and researching products so you don't have to. Learn more.

Our Picks For The Top Serpentine Belt Tools

- 1. JEGS Performance Serpentine Belt Tools, 8-Piece

- 2. Autocraft Tension Releasing Serpentine Belt Tools, 8-Piece

- 3. Powerbuilt 648629 Easy Read Serpentine Belt Tool, 13-Piece

- 4. OEM TOOLS 25149 Multi-Vehicle Serpentine Belt Tool Set, 6-Piece

- 5. Performance Tool W89716 Spring Loaded Serpentine Belt Tool, 16-Piece

- 6. EWK Extra-Long Handle Serpentine Tool Belt Tensioner

- 7. GEARWRENCH Patented Serpentine Belt Tool Set, 15-Piece

- 8. OTC 7654A Ergonomic Serpentine Belt Installation Tool

- 9. CTA Tools 1016 Mini Cooper Serpentine Belt Tool Set, 2-Piece

- 10. Fairmount Tools Spring-Loaded Serpentine Belt Wrench Tool, 6-Piece

- 11. Lisle 59000 Freewheel Serpentine Belt Tool, 11-Piece

Reaching into tight spaces isn't a problem for this serpentine belt tool. The rod comes with seven attachments, so you won't need to make any additional purchases to use the tool. It's also highly recommended by reviewers, who report the tool works as advertised.

Saves TimeThis serpentine belt tool has universal compatibility and can be used with just about any type of vehicle.

Reduce the time you spend working on your car with this serpentine belt tool. It's designed to push the tensioner pulley upward with ease, so you can quickly remove the belt. Also included with this kit are 13, 14 and 15-millimeter crowfoot wrenches.

Most EconomicalYou won't have any trouble sticking to a budget when you go with this affordably priced serpentine belt tool.

The main tool in this kit is built to last from forged steel. The case is likewise sturdy, and makes the various attachments easy to find. The extensions and bar are both low profile and can handle well in tight spaces.

Well-Built ToolSturdy materials make this serpentine belt tool one to last.

The grip on this serpentine belt tool makes tough jobs a bit easier. The length of the bar is also an asset, especially when you add the extension. Both are compatible with 1/2 inch and 3/4 inch square drives.

Plenty of LengthThe bar and extension tool here offer plenty of reach.

Buying Guide

There are tools in a mechanic’s garage that are absolutely necessary and are well suited to a variety of jobs: The ratchet wrench, pliers, a crowbar and the like. Let’s be clear that a serpentine belt tool is not one of those items. It’s specifically designed for one job, although it can be surprisingly adaptable (especially in cramped spaces). But ask any mechanic who has had to that difficult job and they’ll swear by this deceptively simple bar.

First, a little background on the serpentine belt. This aptly-named strip of reinforced rubber is an essential part of the system that drives any component not powered directly by the car’s engine. Most often, that includes but is not limited to the alternator, power steering, emissions control systems and the water pump. As you can imagine, things can go south very quickly if this belt breaks or slips off its pulleys — but it does happen.

The problem is that replacing this simple belt can be a time-consuming activity for any professional mechanic, not to mention an amateur one. The belt snakes over a series of pulleys that are attached to the accessories that it powers, and those pulleys are usually placed far apart in cramped areas towards the front of the engine compartment. In most cars, there is a tension mechanism that you can adjust with a wrench, thereby loosening the belt. Mechanics might need to remove several components like the wheel well or engine cover in order to get enough elbow room to loosen that tensioner — if they’re doing it the hard way.

The easy way is to use a serpentine belt tool. Bear in mind there are actually two types of serpentine belt tools: One specifically designed for getting to and adjusting that pesky tensioner, and the other to help you grab and place the belt.

In its most basic form, the first kind is a long, thin bar with a drive square on one end. Once you put the correct socket on, you’ve got a wrench that can extend down into the hard-to-reach areas under the hood. You can use it to adjust the tensioner without having to take half your car apart, and that can save a lot of time and sweat.

These tools will often come in kits that include not just an array of common sockets for the job, but one or more extension bars. In some cars, the tensioner isn’t just placed in a tight spot; it can also be in an awkward one. Extension bars can be added to the end of a serpentine belt tool, allowing you to get leverage from a variety of angles. In many cases, you can even fasten a standard wrench onto the end of the tool.

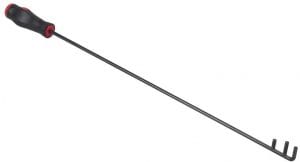

The second kind of serpentine belt tool is used not to loosen the pulleys, but to manipulate the belt itself. Serpentine belts can wind across many pulleys in spots that are even more difficult to access than the tensioner. A serpentine belt installation tool is a long rod with a two or three-pronged fork at the end. This fork is situated at a right angle to the main bar, and the tines are meant to fit between the grooves in the belt. This makes it much easier to grab and stretch over pulleys without having to actually reach them.

In either case, you’ll want it made of sturdy metal. That’s especially true for the first type of serpentine belt tool, which is going to be subject to a lot of pushing and pulling. A selection of the different socket sizes is a big plus, especially if you plan to work on more vehicles than just your own. And don’t overlook the grip: A non-slip rubber handle can make all the difference when you’re leaning into a too-tight tensioner.

Why we recommend these serpentine belt tools?

Products Considered

Products Analyzed

Expert Reviews Included

User Opinions Analyzed

Our experts reviewed the top 11 Serpentine Belt Tools and also dug through the reviews from 2 of the most popular review sites including and more. The result is a ranking of the best of the best Serpentine Belt Tools.

DWYM is your trusted roduct review source. Our team reviews thousands of product reviews from the trusted top experts and combines them into one easy-to-understand score. Learn more.

The Best Bang For Your Buck

Autocraft Tension Releasing Serpentine Belt Tools, 8-Piece

Key Takeawy

Reduce the time you spend working on your car with this serpentine belt tool. It's designed to push the tensioner pulley upward with ease, so you can quickly remove the belt. Also included with this kit are 13, 14 and 15-millimeter crowfoot wrenches.

What to Look For

It’s typically pretty easy to tell if your serpentine belt needs to replaced in the first place. There are even tiny gauges that can measure the acceptable level of wear in your grooves if you really want to do your own diagnosis. But while you’re looking for wear, check your tensioner arm first by giving it a look while the engine is running. A smoothly-operating tensioner should run without wobbling in the belt at all, though the tensioner itself might vibrate slightly. If the tensioner arm is moving side to side by 1/4 inch or more, you may want to have it replaced before it puts more wear onto a new serpentine belt.

More to Explore

Serpentine belts are fairly ubiquitous these days, but they’re actually a fairly recent innovation. The first cars to use a serpentine belt were Ford Mustangs in the late 1970s, thanks to the design of inventor Jim Vance. They quickly caught on, and by the mid-80s were commonplace in most cars.