CURT 18153 Folding Basket Hitch Carrier Auto Cargo Management

Last updated: August 5, 2023

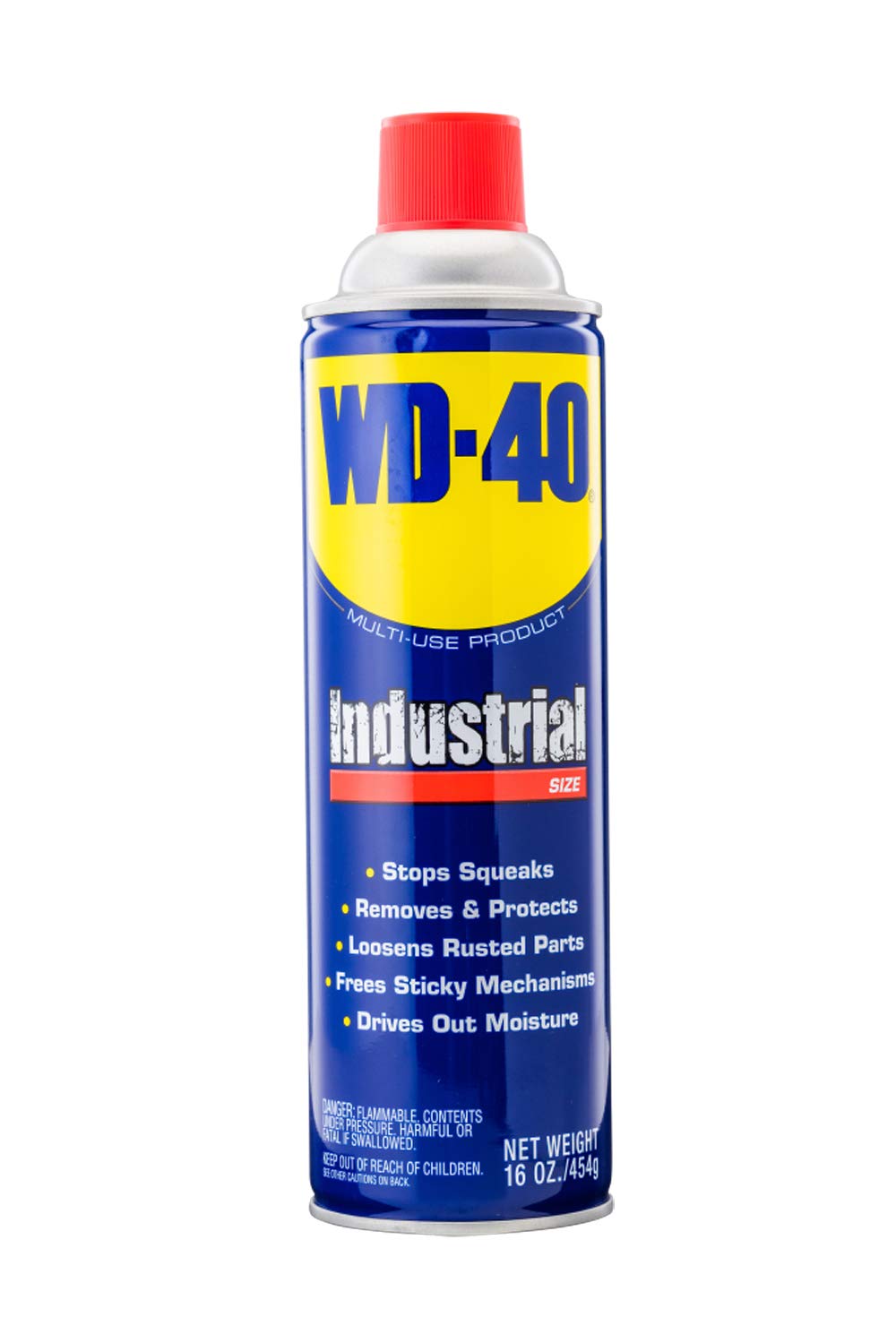

You’ll get 16 ounces of product with this option, along with a spray nozzle to make application easy. It not only lubricates and protects, but it also removes moisture. The formula makes it great for use on everything from wheels to hedge trimmers to bicycles.

We looked at the top Industrial Lubricants and dug through the reviews from some of the most popular review sites. Through this analysis, we've determined the best Industrial Lubricant you should buy.

Product Details

Key Takeaway: A spray nozzle and 16-ounce size makes this a great multipurpose option.

In our analysis of 15 expert reviews, the WD-40 Multi-Use Aerosol Industrial Lubricant, 12-Pack placed 3rd when we looked at the top 6 products in the category. For the full ranking, see below.From The Manufacturer

MULTI-USE AEROSOL SPRAY: With a traditional spray nozzle, this unique lubricant comes in an industrial 16 oz. size. Offering easy to use application, this multi-purpose lubricant helps protect your tools as you tackle big jobs, so you’re ready for anything. ONE FORMULA. FIVE FUNCTIONS: WD-40 Multi-Use Product offers one formula with five functions. It lubricates, penetrates, protects, removes, and displaces moisture. WD-40 Multi-Use Product doesn’t use silicone, kerosene, water, graphite, or chlorofluorocarbons (CFCs). THOUSANDS OF WAYS TO LUBRICATE: This lubricating spray can be used on alloy wheels, engines, hedge trimmers, hinges, bikes, and all the nuts and bolts you throw its way. With long lasting performance and protection, it will get the job done. TOOLKIT IN A CAN: This multi-purpose lubricant is truly a “toolkit in a can”. Harness the power of WD-40 as you get every job done with ease. This formula has been around for over 65 years and has over 2,000 different uses. SAFE FOR ALMOST ANYTHING: WD-40 Multi-Use Product is safe on rubber, metal, wood, and most plastics (avoid use on polycarbonate and clear polystyrene plastic). Use it on your bike to prevent rust or prevent mud from sticking, or on sports equipment like golf clubs and metal baseball bats.

![WD-40 490088 Multi-Use Product, Industrial Size, 16 OZ [12-Pack]](https://m.media-amazon.com/images/I/41J3TY+xmzL.jpg)