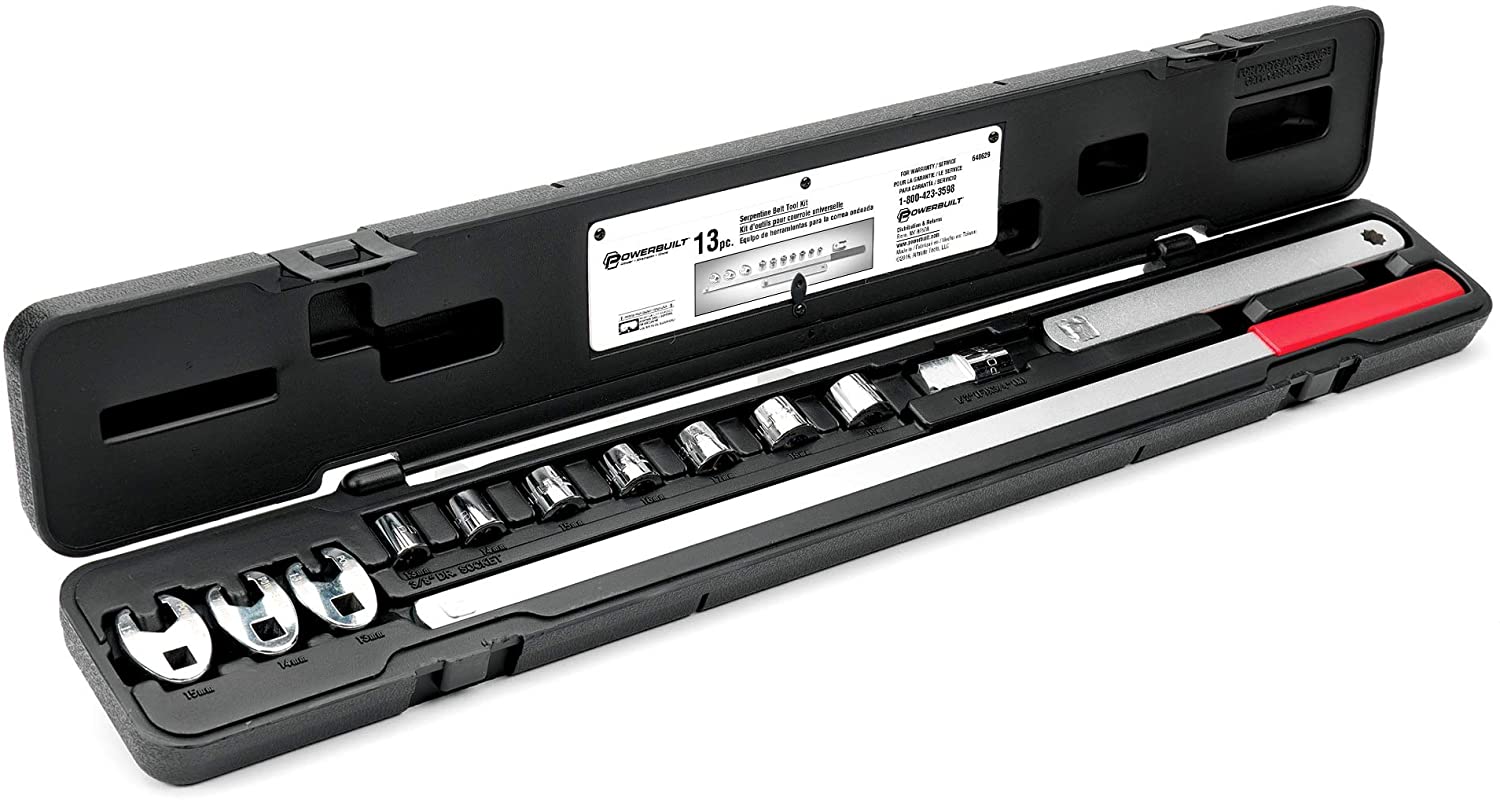

Powerbuilt 648629 Easy Read Serpentine Belt Tool, 13-Piece

Last updated: August 10, 2022

The main tool in this kit is built to last from forged steel. The case is likewise sturdy, and makes the various attachments easy to find. The extensions and bar are both low profile and can handle well in tight spaces.

We looked at the top Serpentine Belt Tools and dug through the reviews from some of the most popular review sites. Through this analysis, we've determined the best Serpentine Belt Tool you should buy.

Product Details

Key Takeaway: Sturdy materials make this serpentine belt tool one to last.

In our analysis, the Powerbuilt Powerbuilt Easy Read Serpentine Belt Tool, 13-Piece placed 3rd when we looked at the top 11 products in the category. For the full ranking, see below.

From The Manufacturer

For more than 38 years, Powerbuilt has offered best in class tools and equipment that deliver quality, innovation and durability to automotive professionals and enthusiasts. Removing the serpentine belt requires loosening the belt tensioner, but sometimes a regular ratchet won’t reach. That’s when you need this innovative serpentine belt tool set.belt. Take the concept of ‘help’ a big step further. The extra-long length lets you reach the deepest bolt and the two piece extension bar/handle design allows you to change the handle angle for increased leverage. Strong and dependable enough to last a lifetime. Any specialty tool will help make an automotive repair or maintenance task easier, but Powerbuilt automotive installer tools take the concept of ‘help’ a big step further. It starts with the storage case – heavy-duty design ensures it will stand up to years of use and abuse. Inside the case lid you’ll find how to instructions and photos that show step-by-step usage instructions. The finishing touch? All Powerbuilt installer kits meet or exceed ANSI and/or ASME standards so you can buy with confidence knowing you’ll get quality.