The Best 3D Printer To Turn Your CAD Dreams Into Reality

Our Review Process

Don't Waste Your Money is focused on helping you make the best purchasing decision. Our team of experts spends hundreds of hours analyzing, testing, and researching products so you don't have to. Learn more.

Our Picks For The Top 3D Printers

There is so much to like about this 3D printer, which was designed with beginners in mind. The unit not only runs quietly, but it also connects quickly to Wi-Fi and features one-button quick leveling. With the printer, you can make everything from a child's toy to a set of prosthetics.

Great for BeginnersThis 3D printer's latest upgrade has increased its speed by 20 percent, allowing you to complete your projects much faster.

You can learn the basics of 3D printer construction while finishing the assembly. It comes partially set up so it’s almost ready to go. It features a resume print function and a safe power supply.

Easy to Set UpThis 3D printer comes partially assembled so you can quickly finish putting it together.

You will get stable and sufficient power with the built-in Meanwell power supply. This ensures that the nozzle and hotbed heat up fast. This printer is easy to assemble in less than 20 minutes.

Stable PowerThis 3D printer has a built-in Meanwell power supply.

Buying Guide

A 3D printer is a marvelous piece of technology that is taking businesses and home offices by storm. In a short amount of time and with the right designs, you have the ability to print almost anything. For example, you can print useful household items like bowls and plates if you accidentally break a piece of your dinnerware. You can print a planter for your new herb garden, or even a simple stationary holder for your desk. If you want to print a small set of cutlery for taking to work or school, you can print out a unique fork, knife and spoon from your 3D printer as well.

In addition to household items, a 3D printer can also print out toys for your kids. Whether they are into dinosaurs or blocks, you can find patterns to print for numerous playthings. From whistles to fidget spinners to toy cars, almost any toy can be created using a 3D printer at home. Plus, you can also print accessories for yourself, like a wallet or orthotics for your shoes. There are endless possibilities to take advantage of when you have a 3D printer.

There are several different types of 3D printers on the market, each with their own advantages. A fused deposition modeling (FDM) printer is a basic one that is loved by beginners to 3D printing. It works by heating a filament and shaping it along X, Y and Z axes. Within this category, there are two different types of FDM printers: cartesian and delta. A Cartesian FDM printer moves the printing bed on the Y axis, while the other two axes move with their own motors. Most FDM printers work this way as it is highly precise. A delta FDM printer has three motors on individual rods, which is not a common model.

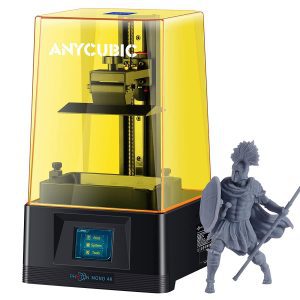

Stereolithography (SLA) printers use a process that involves a chemical reaction to form layers of print. It is a highly precise result with smooth prints. This kind of model is perfect for printing items that require extremely fine printed details. A similar model is the digital light processing (DLP) printer. It works by using light, which targets a specific area of the resin and hardening it into a sculpture.

Both SLA and DLP models produce exceptionally smooth prints as compared to an FDM model, which can have rougher results. If you want to print industrial parts, then a selective laser sintering printer is a good choice. The process it uses involves laser precision, and is good for highly complex designs and detailed items.

In addition to the type of 3D printer you need, you’ll also have to consider what kind of printing materials are best for the objects you want to create. If you’re going with a printer that uses filament, you have a couple of options. Polylactic acid (PLA) is a kind of plastic made from plants. It can be useful for creating items for indoor use. However, it does deteriorate after a lot of sun exposure, so you shouldn’t use it for any items that are kept outdoors. Polyethylene terephthalate glycol (PETG) is a food-safe plastic. If you want to use it to create items like plates or cutlery, you will still need to finish it with a food-grade epoxy. Acrylonitrile butadiene styrene (ABS) is a a highly sturdy plastic that is perfect for items that will be used outdoors.

If your are going with a SLA or DLP printer that uses resin, then you can choose the quality of liquid resin you need based on what you’re making. Standard resin is a good option for small gadgets like pencil holders. Professional resin is best for engineering applications that will see high impact and high usage. Medical-grade resin is often used for making custom dental work or hearing aids.

What to Look For

- The type of 3D printer you need will really depend on the kinds of objects you want to print. That’s why it’s best to consider the range of needs you have before purchasing a printer. For example, if you primarily want to print household objects for indoor use, then you can use an FDM printer. For objects that you will be using outdoors, the type of filament is what will make a difference. You have to use an ABS filament that can withstand the sun. If your goal is to print artwork with your 3D printer, then it’s best to use a resin printer, which will be able to handle the delicacy of your designs, unlike an FDM printer. For tools, opt for an FDM for home use. For professional-grade tools, then you will need to use a resin-based 3D printer.

- An important factor to note for 3D printers is resolution. The resolution for 3D printers is measured in a unit called microns. For example, an FDM printer, which is most common for individual use, has a resolution of 25 microns. Resin-based 3D printers, which are common for professional applications, have a resolution of 100 microns. This means that you will get much finer details on a resin printer. Consider the kind of details you need printed and how smooth the object needs to be. The higher the microns, the higher the precision of the printer.

- In addition to the hardware of the actual 3D printer, you’ll also need software to create the printer files. The software program for your computer, on which you create the 3D printing files, is referred to as a slicer. Popular slicing software includes Cura and Slic3r. There are other slicer software options available as well. Be sure to read reviews online before landing on a 3D printing software for your computer.

- Making a 3D printed object can take time. During the printing process, your printer may be interrupted by a number of issues. As a result, the object that you’re printing can be ruined in progress, wasting resources and time. In order to reduce the amount of unexpected interruptions during the 3D printing process, look for a printer that has a print resume feature. This will ensure that your print isn’t ruined partway through as a result of an issue. If the printer does have to pause, it can easily pick up where it left off with your object.

- The first layers of your printed object are like the foundation of a house. Everything else rests on those layers, and it’s is critical that they are well-formed, stable and staying in place. In order to ensure that the bottom layers of your print are solid, you will need a heated bed. Different types of filament have specific temperatures they require in terms of heat, so you may need to experiment to find what is right for you.

- An intuitive user interface will make all the difference on your 3D printer. If you have one that is manual, such as one with a rotary knob, it can be difficult to navigate. Even a touchscreen that is confusing can cause unnecessary problems with your printing process. Look for a streamlined touchscreen user interface that is easy to understand and doesn’t require complex instructions.

- When you first start using your 3D printer, you may have to adjust the tension of the X, Y or Z axes by tightening or loosening them. Having a printer where the tension belt is easy to access and adjust will make life a lot easier. Otherwise, you will have to figure out how to remove specific components in order to access the tension belt, which require time and intricate knowledge of the printer hardware. Plus, if you aren’t able to put everything back in place the right away, it will cause further issues.

More to Explore

You might not think of it at first, but safety needs to be a top priority when it comes to 3D printers. One of the most important things to note is that when you’re using a 3D printer, you are close to heated plastics. This means that the printing bed can be very hot while printing and shortly after. If you come into contact with the printing bed while it’s on, you can be burned badly due to the high temperature. Some printers have an enclosure around the heated print area, while others are open. Having an enclosure is a good safety measure to look for.

The placement of your 3D printer will affect how well the fumes are ventilated. If you are using ABS plastics, then you will want to ensure that the 3D printer is in a well-ventilated area. This is especially important if you plan on using the 3D printer frequently. You don’t want to be overwhelmed by the fumes and have them cause harm while printing.

Another factor to keep in mind when using 3D printers, especially when making household objects and kitchenware, is food safety. Some filaments are food-grade; however, there may be additional additives in them which are not safe. Items created by 3D printers are porous, which means that bacteria can collect on the surface of the objects. As a result, you shouldn’t use any objects created with a 3D printer without a proper food-grade coating if you want to use them in the kitchen.